To evolve is the law of the universe and Quality is no exception. With technological advances in the past decades have been leading the next wave of revolution across the industries, often referred as fourth revolution or ‘Industry 4.0’.

Technological advancements in fields such as Data, Analytics, Social e-Networking, Scalability and Connectivity are driving not just Innovation but true paradigm shifts in Manufacturing and the delivery of Products and Services. Perhaps more importantly, the ways in which these various factors can interact, present not just an opportunity but a necessity for businesses to adapt to a new industrial reality.

Quality 4.0 is more about aligning the Quality Management Practices with the emerging & advanced technology driven capabilities to achieve Organizational Excellence, beyond mere Process or Operational Excellence.

What is Industry 4.0?

Industry 4.0 is something we have already started living in. This loose concept groups a number of technologies that are reaching a level of maturity enabling them to be implemented and accepted not just in industry (contrary to what is suggested by the name) but in many processes in modern society.

This group of technologies, to name specifically, includes-

1. Industrial Internet of Things (IoT) means equipping elements of the manufacturing environment (complementing manufacturing equipment) with remote sensing technologies that allow more data and information to be collected.

2. 3D Printing offers manufacturers a quick and affordable method to produce prototypes and to showcase new products much faster than with the classical Prototyping Methods.

3. Drones offer a bird’s eye view as they enable oversight over large areas and they can be implemented in dangerous or unreachable areas.

4. Blockchain can offer the solution with full traceability, where trust and reliability are missing in our current processes.

5. Augmented Reality (AR) can support workforce by showing real-time measurement results, tasks etc. It can guide a worker when starting up unfamiliar processes or dealing with new situations.

6. Virtual Reality (VR) offers new means to teach, show and share learnings and experiences.

7. New User Interfaces (UI) brings a new communication method to the industry work floor. Through Chat-Bots or voice control, employees can control and operate devices and machines etc.

8. Robotics offer us a way to perform the same task again and again with a high degree of repetition, not by employing a human but by using a program.

9. Machine Learning (ML) & Artificial Intelligence (AI) enable the processing of big data and it offers the possibility to obtain new insights, for instance in patterns that are currently out of reach. AI also helps identify connections between what we measure and how we should respond to the results.

10. Cloud Computing allows data to be processed remotely (in a cloud) and gives us access to a lot of computing power and memory without the need to set up any infrastructure.

What is Quality 4.0?

Quality 4.0 referred to the future of Quality, within the context of Industry 4.0. The fundamentals of Quality would remain the same, but not the ways of attaining it. Quality Professionals would require to play a vital role in leading their organizations to apply proven quality disciplines to new, digital and disruptive technologies as we have just introduced to.

The concept of Quality 4.0 presents an opportunity for organizations to review the root causes of current barriers to quality success and engage in Strategic Planning to explore how these disruptive technologies and their advantages, such as improved data transparency and high quality data-driven insights, can be leveraged to achieve a Culture of Excellence, not limited to specific process but beyond at large, at the organizational level.

To simply, we can say, Quality 4.0 is nothing but digitisation of Quality Management Practices involving Quality Tools & Technologies, Processes and People.

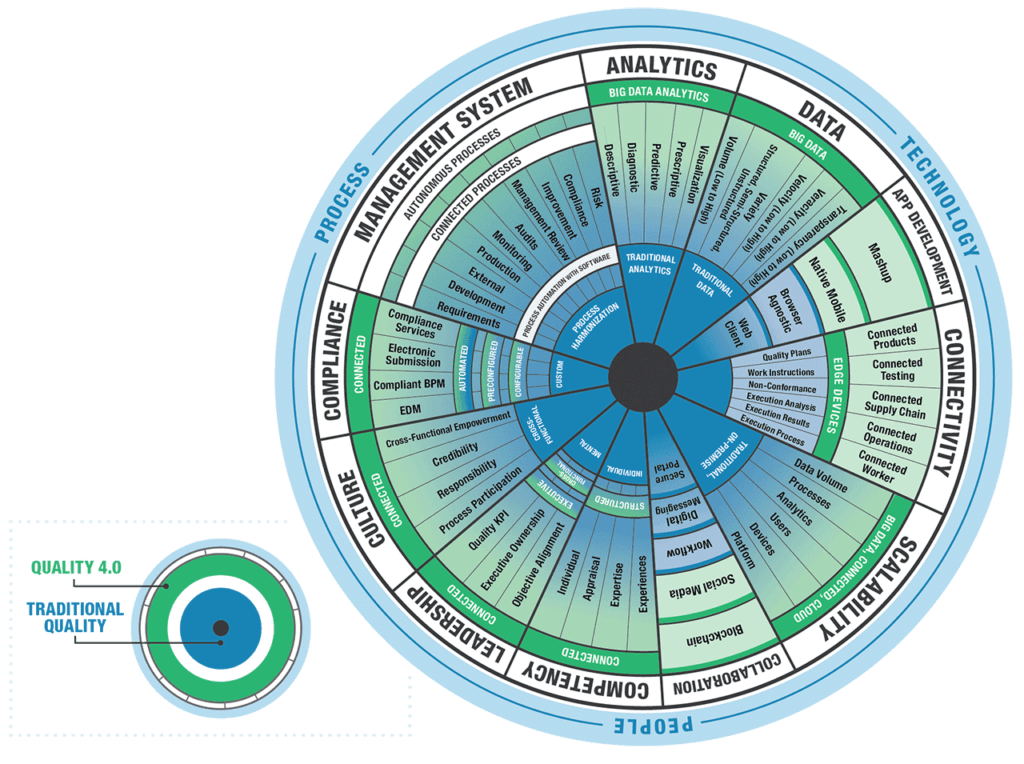

LNS Research, an industry analyst firm focused on best practices in Industrial Transformation for Operations & Technology Leaders, has identified 11 Axes or Pillars of Quality 4.0, which the organizations can use to educate, plan and act.

Using this framework and research, leaders identify how Quality 4.0 can transform existing capabilities and initiatives. The framework also provides a perspective on traditional quality. Quality 4.0 doesn’t replace traditional quality methods, but rather builds and improves upon them. Manufacturers should use the framework to interpret their current state and identify what changes are needed to move to the future state.

Understanding these axes will help you take the first step in adopting a Quality 4.0 approach.

1. Data: Organizations must seek ways to combine data from various systems to ensure accuracy and transparency.

2. Analytics: Organizations should be well-served to develop an Analytics Strategy after or concurrently with a Data Strategy using Big Data, Machine Learning (ML) & Artificial Intelligence (AI).

3. Connectivity: Industry 4.0 enables greater connectivity with inexpensive sensors that connect and provide feedback from people, products and processes. Leaders should make the best use of it.

4. Collaboration: Tech trends such as social listening and Blockchain have transformed collaboration in recent years, and leaders should look to leverage the transformative powers of Connectivity, Data and Analytics.

5. App Development: Organizations should consider the full potential of Interactive Apps available today, including Wearables, Augmented Reality (AR) and Virtual Reality (VR).

6. Scalability: Cloud Computing is of particular importance to Scalability, along with Data Lake Technologies, to support Data Volume, Users, Devices and Analytics on a Global Scale.

7. Management Systems: Harmonizing and Automating Processes and Systems can allow Quality Leaders & Teams to shift their focus from simply executing Quality to Innovating and Improving it.

8. Compliances: Industry 4.0 Technologies deliver Highly Configurable, Automated and Connected QMS Solutions and even offer tools to Automate Validation. Organizations should assess their current Compliance Systems and Strategies to identify where improvements can be made.

9. Culture: The improved Connectivity, Visibility, Insights and Collaboration offered by Quality 4.0 make a culture of Quality attainable.

10. Leadership: Quality 4.0 represents an opportunity for quality teams to clearly align their objectives and practices with strategic aims.

11. Competency: Quality 4.0 encapsulates a variety of technologies that can be utilized to improve competencies in various capacities & resources including human capital.

Why Quality 4.0 is Significant?

It would be a mistake to believe that the range of technologies that together contribute to Industry 4.0 are anything less than transformative in nature. Quality 4.0 represents an opportunity to utilize those Industry 4.0 technologies to realign quality functions with broader organizational strategy.

From a base position where only 13% of organizations believe that quality is a priority for top management, Quality 4.0 provides the scope to both redirect quality activities and to alter the perception of the quality function in organizations as being little more than the ‘Quality Police’.

Developing an effective Quality 4.0 strategy will enable organizations to address long-standing quality issues. For many organizations, these stem from inefficiencies resulting from issues such as lack of cross-functional ownership, ineffective communication, and fragmented traditional quality systems.